CUBIC BORON NITRIDE CUBIC BORON NITRIDE

|

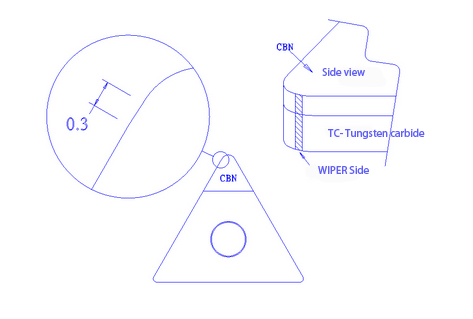

The CBN tool is composed of boron nitride and tungsten carbide base sintered compact.

Boron nitride hardness is only second to PCD, with excellent chemical stability, without chemical affinity with ferrit, cobalt & nickel base alloys!

CBN tools if cutting angle and edge design correctiy, impact resistance can be used in interrupted cutting, due to the awareness of environmental protection.

CBN turning is replacing the traditional grinding greatiy.

| Bending strength | 105 x 103 Psi |

| Elastic coefficient | 125 x 106 Psi |

| Hardness Knoop | 3500 Kg / mm2 |

| Heat conduction | 1~2 Watts / cm o K |

Application of CBN boron nitride cutting tools

CBN tool proposed preliminary cutting data, the application can be used to provide the data in the table as a starting point,

And then with the actual situation to be corrected parameters.

| Materials | Hardness (HRC) | Cutting Speed(m/min) | Feed Rate (mm/rev) | Cutting Depth(mm) |

| Carbon-Steel Alloy | 45~68 | 80~120 | 0.10~0.40 | 0.10~3.00 |

| Chilled Cast Iron | 40~65 | 80~120 | 0.13~0.40 | 0.10~3.00 |

| Sintered Iron | 20~25 | 170~400 | 0.10~0.25 | 0.25~1.30 |

| Surface Hardening Materials | 35 the following | 80~150 | 0.10~0.40 | 0.15~0.60 |

| Heat-resisting Alloy | 40 the above | 100~150 | 0.10~0.40 | 0.15~3.00 |

| Steel rollers | 35 the above | 30~130 | 0.10~0.50 | 0.20~3.00 |

Use the CBN tool should pay attention to matters

1, the machine must be stable, the cutter is left hanging to be short, the clamp should be fixed!

2, as far as possible the use of negative angle blade, such as TNMA1604, VNMG1604....

3, choose a larger angle, or it should be at least 15.

4, cutting conditions with reference to the proposed value.

5, heat resistant alloy or hard machining material, must be chamfered, to prevent the cutter, workpiece edge chipping phenomenon.

6, the use of adequate cutting fluid.

7, the shape of the blade must be particularly careful selection:

CBN negative angle according to the actual processing can be 15 or 20, or 25, or 30, or 35, or 40, or 45 degree.

According to different processing needs, using different angles.

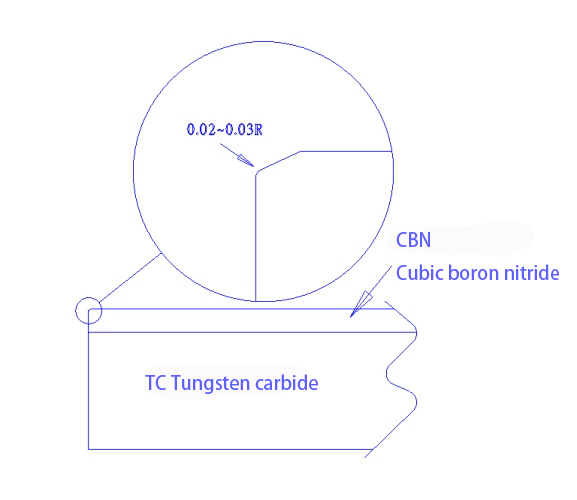

For a better surface roughness and life, there is a kind of Small-radius (honed SRH) processing method,

The original negative angle of the CBN is coupled with a small R angle. (between 0.02~0.05)

According to the experience, after the processing of the SRH CBN tool, its life can be increased by 20~30%,

And has a better surface roughness!

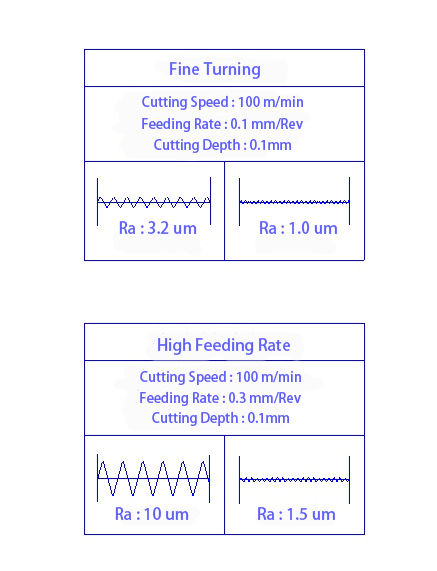

CBN tool application examples

| Material | Cutting speed (m/min) | Feed Rate (mm/rer) | Cutting Depth (m/m) | Size | Effects |

| HSS Round Bar Outside diameter 60˚ | 90 | 0.50 | 0.80 | CNMA1204 | Ra : 10um |

01 Tool-Steel HRC62 | 74 | 0.02 | 0.30 | TNMA1604 | 20 Pcs/Edge Cutting |

M2 HSS Boring HRC62 | 70 | 0.15 | 0.20 | TPGX1103 | Cost Down : 40% |

Inconel 600 HRC40 | 200 | 0.25 | 0.50 | TNMA1604 | Process Time Down 90% 5 Times of T.C |

D4 Tools-Steel HRC65 | 100 | 0.20 | 0.30 | DNMG1504 | Turning Time 14 min / P.C Grinding Time120 min / P.C |

Chilled Cast-Iron HRC62 | 90 | 0.3~0.5 | 2.0 | CNMA1204 | Process Time Down 8 Hrs /P.C |

(WIPER GRINDING)

![]()